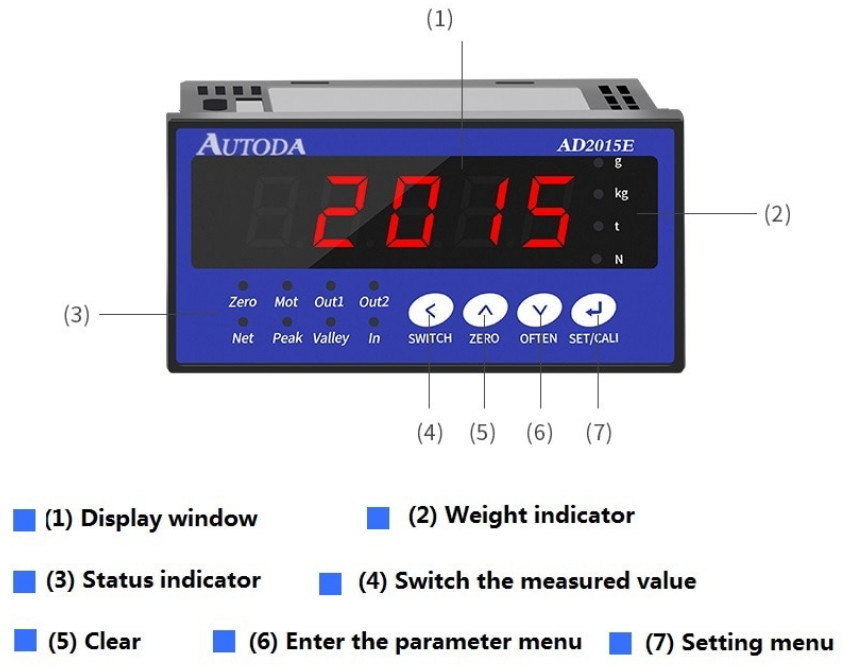

คำอธิบาย

ตัวควบคุม Loadcell ความถูกต้องของจอแสดงผล 1/10,000

- จอแสดงผล 7 Segment 5-Digit

- A/D 24 Bit

- A/D Conversion rate 1,280Hz

- แหล่งจ่ายไฟ Supply voltage DC12V ~ 30V

- Excitation voltage 5VDC ±2%100mA

- เอาต์พุต Rate 10/40/640/1,280 ครั้ง/วินาที

- พอร์ตเอาต์พุต Dual Relay

- RS232 – Communication protocol Modbus RTU/ADCII/FREE

Function

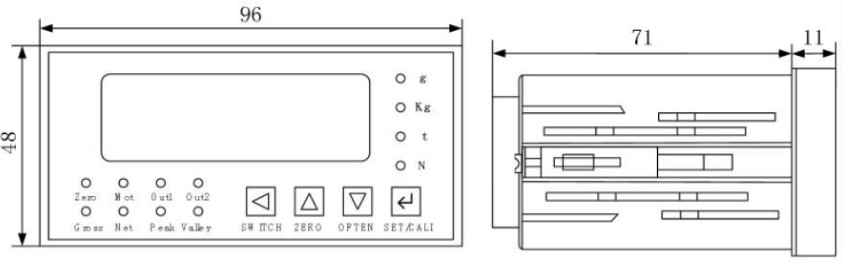

Dimension

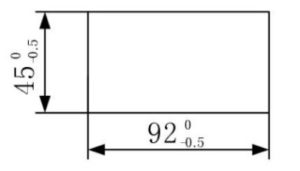

Panel Cut

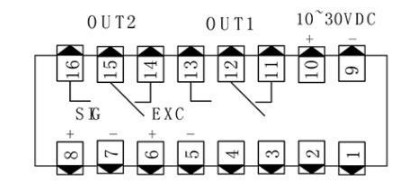

Wiring Terminal Output

การเชื่อมต่อเซ็นเซอร์ โหลดเซลล์/สเตรนเกจ Load Cell

- GND

- RS232 RXD

- RS232 TXD

- NC

- EXC – = Load Cell Excitation –

- EXC + = Load Cell Excitation +

- SIG – = สัญญาณ Load Cell –

- SIG + = สัญญาณ Load Cell +

- + DC IN 10-30V

- GND

- Relay Out1 NC

- Relay Out1 Com

- Relay Out1 NO

- Relay Out2 NC

- Relay Out2 Com

- Relay Out2 NO

ในชุดประกอบด้วย

- 1 x โหลดเซลล์/สเตรนเกจ Load Cell Weighing Control Indicator Box

* ในชุดไม่รวม Load Cell

Datasheet

Modbus-RTU communication protocol

รีวิว

ยังไม่มีบทวิจารณ์